Providing Access to the Working Platform

The Australian Standard AS 1576.1 states that - "Safe access and egress from all working platforms shall be provided. Such access shall take the form of stairways, access ways, ladders and other means". This guide deals with the use of ladders only. For information regarding stair access systems, please consult our technical office. Access towers should be located in the scaffold in such a way that it is not necessary for someone using the scaffold to walk more than 15 metres to an access tower or other means of access and egress. As a "rule of thumb" it is advisable to locate the access tower halfway along the length of any run of scaffold. The recommended bay size for access towers is 2.4m x 1.2m. The procedure is as follows.

|

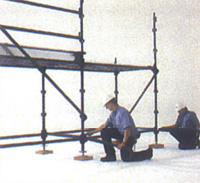

1We need to erect a ladder bay on the rear of the scaffold. Place a 1.2m long transom into the bottom "v" pressing of the outer standard halfway along the length of the run of scaffold. |

|

2Place the sole boards and jacks immediately under the free end of each transom. |

|

3Place a 3m standard on each jack. Attach the transoms to the lower "v" pressings - the 3m standards will allow for handrails at the same height as the working deck. |

|

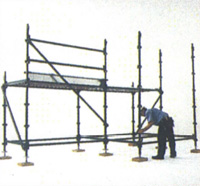

4Place a 2.4m ledger into the lower "v" pressing and level the bay by adjusting the outside jacks. |

|

5Attach the next two transoms into position lat the same height as the transoms on the main scaffold. |

|

6Attach a 2.4m ledger at the same level. Ensure all wedges are knocked in securely. |

|

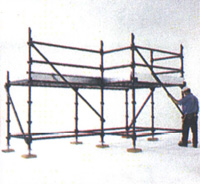

7Attach a ladder tower putlog over the two upper ledgers at the working platform height. Use a 1.2m board between the transom and the transom end on the ladder tower putlog to obtain the correct distance for its final position. |

|

8Place the second 1.2m steel plank between the transom and the angle seating of the ladder tower putlog. Tighten the nut on the ladder tower putlog making sure that the steel planks cannot move laterally. |

|

9Place three 2.4m steel planks on top of and between the two transoms and over the tubular section of the ladder tower putlog. You have now created the first "landing" in the ladder tower bay. |

|

10Fix a double handrail to the outer edges of the landing using 1.2m and 2.4m ledgers. |

|

11Fix toe boards immediately below all handrails. |

|

12Ensure that the bolts on the toe boards are secured using a shifter or spanner. |

|

13An end toe board clip can be used to secure a kick board on the outer side of the scaffold. Attach an end toe board clip using a hammer to locate the wedge. |

|

14Insert a steel board between two end toe board clips. |

|

15Attach a brace to the face of the access bay. On a larger scaffold an end brace should also be attached to one end of the ladder bay. |

|

16The senior erector must now lower a 3.6m ladder into the penetration in the ladder bay landing. Particular care should be taken when handling aluminium ladders - if the ladder has to be stood on end, the risk of accident from contact with power lines is greatly increased as are the risks associated with high winds. The ladder should now be secured against movement in any direction using ladder clips or drop forged doubles to connect the stiles of the ladder to the scaffold ledgers. The pitch of the ladder should be not less than 1 :4 and not more than 1 :6. The ladder should extend at least 900mm and not more than 1800mm above the landing . |

|

17The scaffold is now ready for use and the working platform can be loaded to its maximum evenly distributed safe working load of 650kg per bay !the rectangular area between 4 adjacent standards) per working platform - provided the supporting surface is adequate !see item 3 above). Please note that we recommend that no more than 2 working platforms per bay of scaffold be loaded at any one time. If you wish to use and load multiple working platforms please contact our drawing office for technical advice and guidance. |